- Several typical mechanisms underlying graphene (oxide) nanomaterials toxicity have been revealed, for instance, physical destruction, oxidative stress, DNA damage, inflammatory response, apoptosis, autophagy, and necrosis. In these mechanisms, (toll-like receptors-) TLR-, transforming growth factor β- (TGF-β-) and tumor necrosis factor-alpha (TNF-α) dependent-pathways are involved in the signalling pathway network, and oxidative stress plays a crucial role in these pathways.

- According to the USA FDA, graphene, graphene oxide, and reduced graphene oxide elicit toxic effects both in vitro and in vivo.

- Graphene-family nanomaterials (GFN) are not approved by the USA FDA for human consumption.

60 Uses of Graphene – The Ultimate Guide to Graphene’s (Potential) Applications in 2019

Graphene is a material composed of pure carbon, similar to graphite but with characteristics that make it extraordinarily light and strong. A sheet of one square meter of graphene weighs 0.77 milligrams. Its strength is 200 times greater than that of steel and its density is similar to that of carbon fiber. All these make it resist high bending forces without breaking. It is one of the most conductive materials for electricity and heat, which makes it the perfect material for electronics and many other industries.

For many experts, graphene is the material of the future. Its scientific definition can be considered somewhat complex, but the truth is that the properties of this material open a new horizon in the world of technology.

Its applications are virtually unlimited and promise to revolutionize many fields: from electronics and computing to construction or even health. You can find nearly all applications of graphene in this list – some already commercialized, some need years to materialize.

A reminder: Graphene is called the “wonder material” for a reason. There are tens of research about it which are not published yet, but may change the world tomorrow. On the other hand, some of the potential applications we list here may be disproven in the future either. For this reason, we cannot claim that this list includes all applications of graphene, but unquestionably, it is one of the most inclusive lists of the applications of graphene you can find online.

Disclaimer:

The content of this post or any other linked material is intended for

informational purposes only and should not be taken as medical or

technical advice.

Guide to the list:

Graphene’s Applications in Energy Industry: Items 1-6

Graphene’s Applications in Medicine: Items 7-22

Graphene’s Applications in Electronics: Items 23-34

Graphene’s Applications in Food Industry: Items 35-39

Graphene’s Applications in Sports: Items 40-45

Other Applications of Graphene: Items 46-60

Graphene’s Applications in Energy Industry

1. Graphene in Solar Cells

The idea of developing lighter, flexible and transparent solar cells has been around for a while but finding the material which has all the properties and able to carry the current was the issue. Indium Tin Oxide has been used because it was transparent, however it was not flexible therefore the cell had to remain stiff.

In 2017, researchers from MIT have managed to apply Graphene successfully on a solar cell. When they compared the graphene solar cell with others made of Aluminum and Indium Tin Oxide, they saw that it was as good as the ITO cell, and a little worse than Al one in terms of current densities and power conversion efficiencies. However, it is expected for a transparent cell to perform lower than Aluminum-based, which is nontransparent.

Although electrical properties were not a breakthrough, a solar cell that can be installed on any kind of surface (cars, clothes, paper, and cell phones, etc.) which is flexible and transparent was developed. Moreover, other scientists are trying to find out if graphene solar cells can generate energy from raindrops, which theoretically looks possible.

Read: Use of Graphene in Solar Cells

2. Graphene Batteries

Graphene enhanced Li-ion batteries show incredible characteristics such as longer lifespan, higher capacity, and faster charging time as well as flexibility and lightness, so that it could be used in wearable electronics.

Read: Lithium Ion Batteries vs. Graphene Batteries

3. Graphene in Nuclear Power Plants

Heavy water used in nuclear power plants to cool the reactors is both costly to produce and causes a million tons of CO2 emissions during production. Researchers from University of Manchester have discovered that there is a greener and low-cost method to produce heavy water: graphene membranes. Team leader Dr. Lozada-Hidalgo believes that this innovation is extremely important and its introduction to the nuclear industry will be soon even though this industry is usually skeptical about new technologies.

Read: Graphene for Nuclear Power Plants

4. Graphene in Thermoelectric

Seebeck effect is defined as a thermoelectric effect occurring when heat is applied to one of the two dissimilar electric conductors (or semiconductors) to move the electrons from the hot part to the cooler part and produce electricity. However, the energy generated by this method is really small, usually quantified by microvolts. Still, it is believed that it can be used to benefit from the heat generated by the engines, which is practically wasted. Graphene can be used to increase the Seebeck effect created by Strontium Titanate, almost up to 5 times.

5. Graphene in Alcohol Distillation

Graphene’s physical properties is so interesting and unique that, it would let large water molecules to pass through but stop Helium molecules which could leak through glass. Andre Geim (one of the inventors of Graphene) and Rahul Nair from Manchester University have tried sealing a bottle of vodka with graphene membrane that they have developed, and discovered that graphene could distill ethanol effectively even at room temperature and without the vacuum needed for distillation methods. This area of utilization can be employed in alcoholic beverages, fuel, water purification and so on.

6. Graphene in Fuel Cells

Even hydrogen atoms, known as the smallest atom, cannot pass through Graphene. In another research, Sir Andre Geim and his team have tested if protons would be blocked by graphene or not. Suprisingly, protons could pass through graphene. This property would improve fuel cells performance by lowering the fuel crossover which is a major problem with fuel cells that decreases durability and efficiency.

Read: Fuel Cells’ development with Nanotechnology

Graphene’s Applications in Medicine

Read: Applications of Graphene in Medicine

7. Graphene in Drug Delivery

Functionalized graphene can be used to carry chemotherapy drugs to tumors for cancer patients. Graphene based carriers targeted cancer cells better and reduced and decreased toxicity of the effected healthy cells. Drug delivery is not limited to cancer treatment, anti-inflammatory drugs have also been carried by graphene & chitosan combinations and yielded promising results.

8. Graphene in Cancer Treatment

Graphene can also detect cancer cells in the early stages of the disease. Moreover, it can stop them from growing any further in many types of cancer by intervening the correct formation of the tumor or causing autophagy which leads to the death of cancer cells.

Read: Graphene Shows Potential as Novel Anti-cancer Therapeutic Strategy

9. Graphene in Gene Delivery

Gene delivery is a method used to cure some genetic diseases by bringing foreign DNA into cells. Graphene Oxide modified by Polyethyleneimine can be used for these purposes is expected to show low cytotoxicity, as it did in the drug delivery case.

10. Graphene in Photothermal Therapy

Photothermal therapy (PTT) is a approach used to eliminate abnormal cells in the targeted area of the body by irradiating a special agent which creates heat capable of destructing those cells. Graphene oxide increases effectiveness of PTT by a number of ways. First, it can be used to carry chemotherapeutic drugs to the tumor cells while they are being exposed to PTT simultaneously. Combining chemo and PTT like this is more effective than using one of these approaches alone. A nanocomposite of reduced graphene oxide (QD-CRGO) can be used during PTT for bioimaging of the cancer cells. Moreover, in their research, a group of scientists from Texas Tech and Texas A&M University have shown that using graphene oxide functionalized with biocompatible porphyrin as a platform for PTT for brain cancer have killed more cancer cells than PTT alone, while giving no harm to the healthy cells.

11. Graphene in Diabetes Monitoring

Scientists from the University of Bath have developed a blood glucose monitoring test which does not pierce the skin, unlike currently used finger prick tests. This patch, including a graphene sensor, is able to work on a small area containing at least one hair follicle. It detects the glucose by pulling it from the fluid present between the cells. This does not only end the painful methods of blood sugar monitoring, but is also expected to increase the accuracy of the results.

12. Graphene in Dialysis

Graphene membranes are not only useful for the energy, nuclear and food industries. A group of researchers from MIT showed that graphene can be used to filter the blood from wastes, drugs and chemicals as well. Graphene’s superiority in this case is that it is 20 times thinner than traditional membranes which leads to significant decrease in the time spent in the dialysis for the patients.

Read: Improving Dialysis Process with Graphene

13. Graphene in Bone and Teeth Implantation

Hydroxyapatite, a form of calcium apatite, is a material used as a synthetic bone substitute for regenerated bone and dental tissues. Graphene, combined with Hydroxyapatite and Chitosan, have shown increase in the strength, corrosion resistance, flexibility and mechanical & osteogenic properties of the substitute when compared to HAp alone.

14. Graphene in Tissue Engineering and Cell Therapy

Bones are not the only tissue graphene can cure. Certain forms of graphene were shown to be compatible with human osteoblasts and human mesenchymal cells, showing similar properties with the cells’ physiological microenvironment. Cells grown with this method demonstrated better growth, proliferation, and differentiation while being ineffective on the cells’ viability. Stem cells are especially important in tissue reengineering to improve the lives of people with neuronal disorders or neurodegenerative diseases.

15. Graphene UV Sensors

UV sensors are used for detecting dangerous levels of ultra-violet radiation which can lead to skin problems or even cancer. However, it is not the only use of UV sensors, they are used in the military, optical communication, and environmental monitoring as well. On its own, graphene may not present a high photoresponsivity but when it is combined with other materials, they create flexible, transparent, environmentally-friendly and low-cost UV sensors which will lead to technologies such as wearable electronics in the close future.

Read: Graphene UV Sensors

16. Graphene for the Brain

Mysteries about the brain haven’t been revealed completely yet. A graphene-based technology may allow scientists to uncover many of the unknowns by recording brains electrical activity. This new device is able to hear the frequencies below older technologies’ limits, and it doesn’t interfere with the functioning of the brain. Besides research on how the brain works, the technology can help the scientists to understand the reasons behind epilepsy seizures and develop treatments for the patients. Moreover, discovering more about the brain could lead to developing new Brain-Computer interfaces which are used in many areas including control of prosthetic limbs.

17. Graphene in HIV Diagnosis

Despite all the improvements, there are many drawbacks on current HIV diagnosis methods. They can either detect the antibodies in the body nearly a month later the patient was infected, or they can detect the virus itself however these methods take some time to process themselves and more expensive when compared to the antibody method. A biosensor made of silicon or graphene, containing Gold Nanoparticles was developed by Spanish National Research Council, which targets p24, an antigen found on HIV. The new method can detect the virus only a week after being infected and at levels 100,000 times lower than what the current tests can notice. Moreover, results of the test are ready within 5 hours of being tested.

Read: Fastest HIV Diagnosis with Gold Nanoparticles and Graphene

18. Graphene Biosensors

One of the advantages of graphene is its ability to detect minimal amounts of substances. Even a single molecule in a large volume can be detected with it. Biosensors made of graphene, graphene oxide or reduced graphene oxide show ultrasensitive properties when detecting DNA, ATP, dopamine, oligonucleotides, thrombin, and different atoms. There are several medical companies that already sell medical sensors made with graphene.

Read: Health Sensors from Graphene Sheets

19. Graphene Bactericide

Graphene is a magnificent bactericidal material as it avoids the generation of microorganisms, such as bacteria, viruses, and fungi, by damaging their cell membranes between its outer layers. When compared to different derivatives of Graphene, Graphene Oxide and reduced Graphene Oxide shows the best antibacterial effects. GO can also be used as a compound with silver nanoparticles to increase antibacterial properties even further.

20. Graphene in Birth Control

Graphene has all the properties that is desired in a condom: it is flexible, extra strong and extremely thin. Researchers from Manchester University have worked on developing a “supercondom” made of graphene and latex combined. The research has received many funding, including one from Bill and Melinda Gates Foundation.

21. Graphene in Deaf-Mute Communication

A group of Chinese scientists have developed a wearable, bio-integrated device that can translate sign language into text and spoken language. The device uses graphene’s incredible conductivity and flexibility properties.

Read: New Way of Deaf-Mute Communication with 3D Graphene

22. Graphene in Body Scans

Unlike X-rays, T-waves which can be used for body scanning are harmless to human body. However, there is a catch. T-waves, or THZ radiation, is hard to both detect and generate. The good news is, with the help of some modifications and other materials, CVD graphene can detect THZ radiation successfully. This will not only lead to safer body scans, but also incredibly faster internet in the future.

Graphene's Applications in Electronics

Read: Use of Graphene in Electronics

23. Graphene in Generating Light

Researchers at MIT have discovered that when light hits the surface of graphene, it’s slowed down and the photons started moving in a speed very close to the speed of electrons which increases when moving on graphene. This coincidence makes it possible to break the light barrier for electrons and creates light. The advantage of this method over the conventional ways of generating light such as fluorescent or LEDs is that it’s expected to be more efficient, faster, compact and controllable, and it looks like generating light from graphene will be a key milestone in developing even smaller, faster and more efficient computer chips.

24. Graphene Transistors

The new supertransistors, which replace silicon with graphene, can increase the speed of computers up to one thousand times when compared to current technology. Increasing speed of computers is a crucial step for many technologies to be able to improve, including but not limited to blockchain, simulations of the outer space, robots, and stock markets.

Read: Meet the World’s Fastest Transistor with Graphene

25. Graphene in Waterproof Electronics

One of the main problems of electronic devices which people are afraid of is being dropped to water. Instead of covering the device with tight-fitted screws, graphene proposes a great solution for this problem. Engineers from Iowa State University print the circuits of the device with graphene flakes because graphene is transparent, strong and conducts electricity. Graphene flakes are arranged in a specific order and non-conductive binders are used to combine them which improved the conductivity. As in the most application areas, graphene again puts a great solution to this problem.

26. Graphene in Wearable Electronics

Researchers are looking for new ways to power wearable devices. One of the outstanding ways is flexible batteries printed on a fabric with graphene. This enables people to wear their batteries and power their smartphones or other devices, literally. If this can be achieved, it will be an environmentally friendly and smart e-textile that can store energy. Carrying heavy power-banks or chargers will be history by the invention of this amazing idea.

27. Graphene for Touchscreens

Indium tin oxide (ITO) is the commercial product used as transparent conductor of the smartphones, tablets, and computers. Researchers from the Rice University have developed a graphene-based thin film to be used in touchscreens. It is found that graphene-based thin film beats ITO and any other materials in terms of performance because it has lower resistance and higher transparency. Thus, Graphene is the new candidate material for the replacement of ITO.

28. Graphene in Flexible Screens

The world of technology would be one of the great beneficiaries of the standardization of graphene as a material to incorporate in products such as smartphones or tablets. It would be the definitive step to advance in the world of smartphones.

Recently, a Chinese company has produced a bendable smartphone with a graphene touch screen. Since one layer of graphene is strong, light, transparent and very conductive, it meets all the requirements for the production of smartphones. The smartphone of the Chinese company has the ability to wrap a twist completely, and it weighs only 200 grams which propose a perfect convenience for usage. However, production of graphene is expensive at an industrial scale relative to other materials used in smartphones. Researchers are looking for ways to produce graphene at lower costs. When this problem and some others are solved, old phones seem to be replaced by these flexible smartphones in the future.

Discover Nanografi’s Greengraphene project, producing highest quality Graphene with environmentally friendly methods and lowest costs: Nanografi’s EU Horizon2020 winner project: GREENGRAPHENE

29. Graphene in Hard Drives and Memories

Usually, graphene is not considered magnetic, at least not in a controllable or useful way. In 2015, researchers from U.S. Naval Research Laboratory have found a way to turn graphene into a reliable and controllable electromagnetic material. If this innovation is used in hard drives, it is expected to have a capacity almost a million times greater than what we use today.

30. Graphene in Elastic Robots

A team of researchers has developed a gel that is sensitive to near infrared light so that it could be used in numerous applications when creating flexible or elastic robotic parts. The snake-like robots created with this method are able to change its form without any forces from the outside. Their future applications can vary from search-and-rescue to medical operations.

31. Graphene as a Superconductor

Scientists have discovered that graphene can also be used as a superconductive material. Two layers of Graphene can conduct the electron without any resistance. This can be accomplished by twisting these two layers of graphene at a ‘magic angle’ which is 1.1°. Most of the superconductive materials show their properties at temperatures close to absolute zero. Even High temperature superconductive materials relative to usual ones can work at around -140°C. In other words, these superconductive materials require a huge energy for cooling. If graphene can be used as a superconductive material at temperatures close to room temperature, there will be a huge revolution for many application areas.

32. Graphene in Optoelectronics

Researchers are working on a new material for the optical communications since energy and power requirement increase as the time passes. A research conducted by the collaboration of different universities has shown that integrating graphene with silicon can beat current silicon photonic technology. How can it beat the current state of art? Because devices made by graphene are cheaper, simpler and work at high-scale wavelengths. Apparently, graphene will present a low-energy optical telecommunication and many other convenient optical systems.

33. Graphene in Optical Sensors

Graphene has a lot of breakthroughs in industry and science owing to its super properties. Researchers tried to shrink the light to make optical sensors smaller. Recently, the Institute of Photonic Sciences (ICFO) in Barcelona, with the collaboration of Graphene Flagship team, conducted a study which explains the reduction of light down to just a single atom thick which is thought to be impossible by many researchers. This discovery will lead to a huge step in ultra-small optical sensors and switches.

34. Graphene Security Sensors

One of the first practical and real applications of graphene was security labels. Instead of the bulky sensors that many stores use, the sensors made with graphene are smaller, more aesthetic, able to bend without creating a damage on the circuit, and cost only a couple cents per tag.

Graphene’s Applications in Food Industry

35. Graphene in Food Packaging

Graphene can also be used as a coating material because it prevents the transfer of water and oxygen. Graphene membranes can be used in food or pharmaceutical packaging by keeping food and medicines fresh for longer time. It may seem a simple application, but it can dramatically reduce the amount of food waste people throw away every day.

36. Graphene in Water Purification

Normally, water purification is not a simple process and feasibility of the process depends on how heavily the water is contaminated. An Australian scientist has found a low-cost technique to purify water at one step. Soybean-based graphene, which is also called ‘GrapHair’, is used as a filter. This filter can make the dirtiest water drinkable. it is more efficient, cheaper and environmentally friendly compared to other methods.

Read: Use of Graphene in Water Filtration

37. Graphene in Desalination

Approximately, 97.5% of the total water present on the planet is salty. It does not matter how many wells we excavate, only 2.5% of the total is fresh water. The filters based on meshes that use graphene have yielded amazing results. The University of Manchester employed graphene to make filtering sieve that has higher density and permit the water particles to pass but prevents the salts.

38. Graphene in Crop Protection

Graphene is a great material for sensors. Micro-sized sensors can be produced thanks to graphene’s unique structure. It can detect whether a molecule is dangerous or not for the environment. These sensors can be used in food industry, especially in crop protection. Farmers can track and detect dangerous and harmful gasses to crop and they can determine the ideal areas for the growth of the crop depending on the atmospheric conditions, and even the moisture level and “thirst” of the plants with the help of graphene sensors.

39. Graphene for Food Security

Studies done by US Rice University have shown that laser-induced graphene can be applied to various substances such as wood, bread, coconut, etc. It may seem like a substance with a pattern on it printed with ink, but it is not. The laser carburizes the material and carburized material is converted into graphene. Any pattern that is desired can be achieved by this technique. Issues that are related to food security can be overcame by this technique.

Graphene's Applications in Sports

40. Graphene in Shoes

Graphene sneakers? Yes, although in this case it is not used purely, other composite materials take advantage of it. In fact, it is claimed that a sole made of pure graphene could last hundreds of years. University of Manchester and sports brand Inov-8 developed a shoe using graphene which increases the outsoles’ strength and flexibility properties by 50%. These shoes are more durable and absorbs the impacts which could damage the bones and joints.

41. Graphene in Helmets

An ideal helmet would be strong, resistant to impact, durable, comfortable, and light. Graphene is incredibly strong, light, and flexible. It’s even used in bulletproof vests, so it can definitely resist impacts. With these properties, graphene is commercially used in motorbike helmets.

42. Graphene in Tires

Graphene is also used to make smarter tires and sports bike components. Adding graphene to bike’s tires apparently increases the puncture resistance and velocity, decreases rolling resistance and makes them way lighter, stronger, faster, and more resilient.

Read: Graphene Tires and Graphene Brake Pads

43. Graphene Clothes

The use of graphene fibers in fabrics offers antibacterial, and anti-static clothes which can preserve the heat and block UV. These fabrics can be used to create outdoor sportswear, pajamas for children that repel soil bacteria, or even household furniture to prevent the development of bacteria on its surface.

44. Graphene Rackets

Graphene can improve the energy distribution and weight of the racket while increasing the service speed and stability. Tennis equipment manufacturer Head have already developed a series of commercially available racket enhanced with graphene, named “Graphene 360” which is already used by tennis stars like Novak Djokovic and Sascha Zverev.

45. Graphene Electronic Tattoos and Fitness Tracking

Graphene Electronic Tattoo (GET) is developed by scientists at the University of Texas. First, they are more resistant to moisture, have a greater elasticity - with the ability to grow or shrink up to 40%, have a total thickness of 463 ± 30 nm, and have optical transparency of approximately 85%. They are like a second skin. These tattoos can be used to track heart rate, temperature, hydration levels, oxygen saturation and even the level of exposure to UV. Their application areas can vary from fitness tracking to medicine.

Other Applications of Graphene

46. Graphene and Silk

Researchers in China have conducted a research to enhance the properties of silk which has already great characteristics. Silkworms eat white mulberry leaves. Researchers sprayed a solution having 0.2 percent graphene on the leaves and let the silkworms eat that leaves. Findings were promising because commercial silkworms fed by graphene sprayed leaves give ten times more than what a usual silkworm can. While it is uncertain how much of the graphene is digested by silkworms, this study will have a positive effect on smart clothing which is a hot topic of the recent years.

Read: Feeding Silkworms with Carbon Nanotube or Graphene to Spin Super Silk

47. Graphene in Cement

Potential application areas of graphene expand as the time passes. One of the important potential usages of graphene is construction industry because graphene is strong and light at the same the which is perfect for construction. It can be used instead of steel, but strength and weight are not the only parameters. Graphene’s the main problem is that crack propagates very fast in graphene which can cause catastrophic failures. Researchers are trying to find ways for using graphene in construction. A group of researchers from University of Exeter used graphene in cement as a reinforcement material and tested. As a result, 2.5 times stronger and 4 times less water permeable concrete was obtained which proves that graphene can be a great reinforcement material in construction.

Read: Use of Graphene in Construction

48. Graphene in Insulation

Graphene can be used as a superconductor or insulator material when two sheets of graphene are arranged at a magic angle. Most of the metal parts of the cars, ships or planes suffer from rusting. When graphene is combined with paint, it can be a great insulation material for creating rust-free surfaces. Another application can be coating of bricks and stones. In this way, water-proof houses can be constructed.

Read: Use of Graphene in Construction

49. Graphene in Speakers and Headphones

A speaker converts electricity into sound by vibrating a membrane in the air. Graphene is used to make lightweight and great rigidity membranes. Moreover, headphones use a small diaphragm reinforced with graphene. GrapheneQ, a headphone developed by the company ORA Sound is lighter and smaller, and at the same time it can reach louder and higher quality sounds with less energy.

Read: Graphene Speaker

50. Graphene in Photography

Due to its exceptional properties and high sensitivity to ultraviolet, visible and infrared lights, graphene seems to be one of the ideal materials to push digital photography and any discipline where optical modulators and photoreceptors are involved. Cameras’ sensors enhanced with graphene and quantum dot can be smaller and lighter while achieving greater resolution levels than any small sensor could up until now.

51. Graphene in Automotive

The extraordinary strength and hardness of graphene, coupled with its flexibility, is perfect to start creating cars that are immune to shocks. Moreover, accident-proof vehicles could also be created. This would result in a direct decline in road mortality. Graphene cars, which we may see in the showrooms within a decade, are also expected to be cheaper and lighter.

52. Graphene in Airplanes

Scientists from UK have designed an airplane that includes graphene in the carbon-fiber coating of the aircraft’s wings. The model plane, Prospero, was lighter since it was enough to cover the wings with only one layer of the improved composite. It consumes less fuel, resists impact better, and has lower environmental costs as well.

Read: Graphene's Use in the Aerospace Industry

53. Graphene Paints

Every painter knows it very well: humidity is the number one enemy of painting. Graphenstone is a company that makes graphene painting solutions. The result? The light bounces better, protects barrels and basements, absorbs 120 grams of CO2 per square meter and is able to withstand the corrosion derived from contact with metals.

Read: Use of Graphene in Construction

54. Graphene in Ballistics

Kevlar is used in the manufacturing of bulletproof vests, helmets and protective clothing and even weapons. But graphene has much greater malleability and is medically safer in case of accident and contact with the bloodstream. Moreover, Kevlar and graphene composites are lighter to wear, and increases heat absorption for the protection of the fibers, when compared to Kevlar on its own.

Read: Military Applications of Graphene

55. Graphene in Military Protective Equipment

One of the future uses that have been raised for graphene is destined for the arms industry. In particular, its usefulness would be aimed at shielding and protection. It could be used in making helmets, bulletproof vests, and many more accessories. It could, in fact, be a determining material for the future of police forces and armies.

Read:Military Applications of Graphene

56. Graphene in Thermal and Infrared Vision

A great advance that we could see is the development of graphene lenses that allows thermal and infrared vision. The graphene allows manufacturing such ultrathin devices with a built-in camera that gives the user an infrared and thermal vision. Something that until now we have only seen in science fiction movies.

57. Graphene in Machinery Lubricants

Industrial machines mostly suffer from friction because friction affects the durability, strength, efficiency and working life of the machines negatively. To minimize these effects, solid or liquid lubricants are used. Recently, graphene, which has countless potential application areas, has started to shine out on this subject. Why graphene? Because it offers perfect friction and wear properties compared to conventional materials. It can also serve as solid or liquid lubricant. In addition, having a great chemical inertness, smooth and densely packed surface makes graphene a great lubricant material.

Read: No Friction with the help of Graphene

58. Graphene in Corrosion Protection for Glass

One of the application areas of graphene is that it can be used as a coating material for glass. Although glass is a high resistant material to corrosion, it can corrode under some conditions such as high humidity or extreme pH values. Also, durability of the glass can be vital in some areas such as pharmaceutical or optical industries. It prevents any type of failure such as corrosion, oxidation, electromagnetic radiation. Graphene with high transparency and high chemical inertness can be a promising material for the protection of glass.

Read: Protection of Glass from Corrosion with Graphene

59. Graphene in Radiation Shielding

Scientists have been trying to keep the radiation at minimum since it is very dangerous for human health. For this purpose, a variety of materials can be used as a shielding material to radiation but there are many parameters that affects the efficiency of shielding. Graphene is known as a weak radiation absorber, but scientists have found that it can be a great shielding material when it is used in multi-layered form which are graphene slabs. Graphene is an outstanding material for this purpose thanks to its low manufacturing cost, light weight and high efficiency compared to any other shielding materials.

Read: Graphene Radiation Shielding

60. Graphene for Anti-corrosion Oil and Gas Pipes

Underwater pipes

used to carry oil or gas is subject to corrosion over time, as CO2 and water is

able to get through the outer layers sometimes. Repairing them is costly, and if

they break due to the corrosion, they would release the content which may be

toxic to aquatic life. Researchers from the University of Manchester and the technology firm TWI have developed a coating with

graphene nanoplatelets and tested it under the temperature and pressure conditions

the pipes would face under the sea. The result was that, CO2 permeability was

decreased by 90%, and lowered the permeability of other corroding agents as

well.

https://nanografi.com/blog/60-uses-of-graphene/

___

Informative video on #GrapheneOxide

— Graviola Finland (@GraviolaDOTfi) September 15, 2021

These were never “vaxxs” against a virus, instead all the time it was a secret nanotech project developed to reach and control the brains of the human population. https://t.co/i6tFM5crqB pic.twitter.com/PsnsDyamG2

___

CLARIFICATION OF THE PRELIMINARY REPORT ON THE PRESENCE OF #GRAPHENE IN #COMIRNATY TM #mRNA VACCINE | July 2021https://t.co/8lZoz6hmqb

— Graviola Finland (@GraviolaDOTfi) August 11, 2021

A pdf of this statement can be found electronically signed in the profile | July 23, 2021 https://t.co/j7qPWLlzWs pic.twitter.com/bAF8tuej9z

___

#SoyUAL #Spanish researchers - La Quinta Columna - The Fifth Column:

— Graviola Finland (@GraviolaDOTfi) August 13, 2021

“#Covid” Symptoms | How to Remove #GrapheneOxide From the Body #Inhaled graphene oxide causes #inflammation of the #mucous membranes and thus possible LOSS OF TASTE AND SMELL : #Anosmia.https://t.co/d1p6bHVwiy pic.twitter.com/cgM9WAEKy0

___

#GrapheneOxide is ‘sensed’ by specialized immune cells

— Graviola Finland (@GraviolaDOTfi) August 18, 2021

- GO being attacked by #neutrophils which are, let’s say, cells of the immune system that try to phagocytize it, try to engulf it: to coagulate it.

That’s why mRNA generates #bloodclots and #thrombi. https://t.co/ben0nchS5l pic.twitter.com/UpFZrekZGC

___

#Nuremberg Trials 2.0 The Int. Criminal Court for #CrimesAgainstHumanity, July 4th 2021

— Graviola Finland (@GraviolaDOTfi) July 3, 2021

- Nuremberg Trials 2.0 #live on ZOOM July 4th 2021 @ 8AM PST https://t.co/Eu6JF51JEr pic.twitter.com/7e0xhZI0oY

___

Graphite oxide

Graphite oxide, formerly called graphitic oxide or graphitic acid, is a compound of carbon, oxygen, and hydrogen in variable ratios, obtained by treating graphite with strong oxidizers and acids for resolving of extra metals. The maximally oxidized bulk product is a yellow solid with C:O ratio between 2.1 and 2.9, that retains the layer structure of graphite but with a much larger and irregular spacing.[2][3]

The bulk material spontaneously disperses in basic solutions or can be dispersed by sonication in polar solvents to yield monomolecular sheets, known as graphene oxide by analogy to graphene, the single-layer form of graphite.[4] Graphene oxide sheets have been used to prepare strong paper-like materials, membranes, thin films, and composite materials. Initially, graphene oxide attracted substantial interest as a possible intermediate for the manufacture of graphene. The graphene obtained by reduction of graphene oxide still has many chemical and structural defects which is a problem for some applications but an advantage for some others.[5][6]

History and preparation

Graphite oxide was first prepared by Oxford chemist Benjamin C. Brodie in 1859, by treating graphite with a mixture of potassium chlorate and fuming nitric acid.[7] He reported synthesis of "paper-like foils" with 0.05 mm thickness. In 1957 Hummers and Offeman developed a safer, quicker, and more efficient process called Hummers' method, using a mixture of sulfuric acid H2SO4, sodium nitrate NaNO3, and potassium permanganate KMnO4, which is still widely used, often with some modifications.[2][8][9] Largest monolayer GO with highly intact carbon framework and minimal residual impurity concentrations can be synthesized in inert containers using highly pure reactants and solvents.[10]

Graphite oxides demonstrate considerable variations of properties depending on degree of oxidation and synthesis method.[11][12] For example, temperature point of explosive exfoliation is generally higher for graphite oxide prepared by Brodie method compared to Hummers graphite oxide, the difference is up to 100 degrees with the same heating rates.[13] Hydration and solvation properties of Brodie and Hummers graphite oxides are also remarkably different.[14]

Recently a mixture of H2SO4 and KMnO4 has been used to cut open carbon nanotubes lengthwise, resulting in microscopic flat ribbons of graphene, a few atoms wide, with the edges "capped" by oxygen atoms (=O) or hydroxyl groups (-OH).[15]

Graphite (Graphene) oxide (GO) has also been prepared by using a "bottom-up" synthesis method (Tang-Lau method) in which the sole source is glucose, the process is safer, simpler, and more environmentally friendly compared to traditionally "top-down" method, in which strong oxidizers are involved. Another important advantage of Tang-Lau method is control of thickness, ranging from monolayer to multilayers by adjusting growth parameters.[16]

Structure

The structure and properties of graphite oxide depend on particular synthesis method and degree of oxidation.[11][12] It typically preserves the layer structure of the parent graphite, but the layers are buckled and the interlayer spacing is about two times larger (~0.7 nm) than that of graphite. Strictly speaking "oxide" is an incorrect but historically established name. Besides oxygen epoxide groups (bridging oxygen atoms), other functional groups experimentally found are:[11] carbonyl (C=O), hydroxyl (-OH), phenol, for graphite oxides prepared using sulphuric acid (e.g. Hummers method) also some impurity of sulphur is often found, for example in a form of organosulfate groups .[17][18][19][20][21][22] The detailed structure is still not understood due to the strong disorder and irregular packing of the layers.

Graphene oxide layers are about 1.1 ± 0.2 nm thick.[17][18] Scanning tunneling microscopy shows the presence of local regions where oxygen atoms are arranged in a rectangular pattern with lattice constant 0.27 nm × 0.41 nm [18][23] The edges of each layer are terminated with carboxyl and carbonyl groups.[17] X-ray photoelectron spectroscopy shows presence of several C1s peaks, their number and relative intensity depending on particular oxidation method used. Assignment of these peaks to certain carbon functionalization types is somewhat uncertain and still under debates. For example, one of interpretations goes as following: non-oxygenated ring contexts (284.8 eV), C-O (286.2 eV), C=O (287.8 eV) and O-C=O (289.0 eV).[24] Another interpretation using density functional theory calculation goes as following: C=C with defects such as functional groups and pentagons (283.6 eV), C=C (non-oxygenated ring contexts) (284.3 eV), sp3C-H in the basal plane and C=C with functional groups (285.0 eV), C=O and C=C with functional groups, C-O (286.5 eV), and O-C=O (288.3 eV).[25]

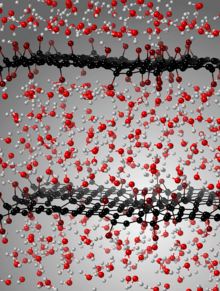

Graphite oxide is hydrophilic and easily hydrated when exposed to water vapor or immersed in liquid water, resulting in a distinct increase of the inter-planar distance (up to 1.2 nm in saturated state). Additional water is also incorporated into interlayer space due to high pressure induced effects.[26] Maximal hydration state of graphite oxide in liquid water corresponds to insertion of 2-3 water monolayers, cooling the graphite oxide/H2O samples results in "pseudo-negative thermal expansion" and below freezing point of water media results in de-insertion of one water monolayer and lattice contraction.[14] Complete removal of water from the structure seems difficult since heating at 60–80 °C results in partial decomposition and degradation of the material.

Similar to water, graphite oxide also easily incorporates other polar solvents, e.g. alcohols. However, intercalation of polar solvents occurs significantly different in Brodie and Hummers graphite oxides. Brodie graphite oxide is intercalated at ambient conditions by one monolayer of alcohols and several other solvents (e.g. dimethylformamide and acetone) when liquid solvent is available in excess. Separation of graphite oxide layers is proportional to the size of alcohol molecule.[29] Cooling of Brodie graphite oxide immersed in excess of liquid methanol, ethanol, acetone, and dimethylformamide results in step-like insertion of additional solvent monolayer and lattice expansion. The phase transition detected by X-ray diffraction and DSC is reversible; de-insertion of solvent monolayer is observed when sample is heated back from low temperatures.[30] Additional methanol and ethanol monolayer is reversibly inserted into the structure of Brodie graphite oxide also at high pressure conditions.[29]

Hummers graphite oxide is intercalated with two methanol or ethanol monolayers already at ambient temperature. The interlayer distance of Hummers graphite oxide in excess of liquid alcohols increases gradually upon temperature decrease, reaching 19.4 and 20.6 Å at 140 K for methanol and ethanol, respectively. The gradual expansion of the Hummers graphite oxide lattice upon cooling corresponds to insertion of at least two additional solvent monolayers.[31]

Graphite oxide exfoliates and decomposes when rapidly heated at moderately high temperatures (~280–300 °C) with formation of finely dispersed amorphous carbon, somewhat similar to activated carbon.[28]

Characterization

XRD, FTIR, Raman, XPS, AFM, TEM, SEM/EDX,[11][32][33][25] etc. are some common techniques to characterize GO samples.[34] Experimental results of graphite/graphene oxide have been analyzed by calculation in detail.[35][36] Since the distribution of oxygen functionalities on GO sheets is polydisperse, fractionation method can be used to characterize and separate GO sheets on the basis of oxidation.[11] Different synthesis methods give rise to different types of graphene oxide. Even the different batches from similar oxidation method can have differences in their properties due to variations in purification or quenching processes.[11]

Surface properties

It is also possible to modify the surface of graphene oxide to change its properties.[33][37] Graphene oxide has unique surface properties which make it a very good surfactant material stabilizing various emulsion systems.[33][11] Graphene oxide remains at the interface of the emulsions systems due to the difference in surface energy of the two phases separated by the interface.[38][33]

Relation to water

Graphite oxides absorb moisture proportionally to humidity and swells in liquid water. The amount of water absorbed by graphite oxides depends on the particular synthesis method and shows a strong temperature dependence.

Brodie graphite oxide absorbs selective methanol from water/methanol mixtures in certain range of methanol concentrations.[40]

Membranes prepared from graphite oxides (recently more often named as "graphene oxide" membranes) are vacuum tight and impermeable to nitrogen and oxygen, but are permeable to water vapors. The membranes are also impermeable to "substances of lower molecular weight". Permeation of graphite and graphene oxide membranes by polar solvents is possible due to swelling of the graphite oxide structure.[41] The membranes in swelled state are also permeable by gases, e.g. helium. Graphene oxide sheets are chemically reactive in liquid water, leading them to acquire a small negative charge.[39]

The interlayer distance of dried graphite oxides was reported as ~6–7 Å but in liquid water it increases up to 11–13 Å at room temperature. The lattice expansion becomes stronger at lower temperatures. The inter-layer distance in diluted NaOH reached infinity, resulting in dispersion of graphite oxide on single-layered graphene oxide sheets in solution. Graphite oxide can be used as a cation exchange membrane for materials such as KCl, HCl, CaCl2, MgCl2, BaCl2 solutions. The membranes were permeable by large alkali ions as they are able to penetrate between graphene oxide layers.[41]

Applications

Optical nonlinearity

Nonlinear optical materials are of great importance for ultrafast photonics and optoelectronics. Recently, the giant optical nonlinearities of graphene oxide (GO) has been proved useful for a number of applications.[42] For example, the optical limiting of GO are indispensable to protect sensitive instruments from laser-induced damage. And the saturable absorption can be used for pulse compression, mode-locking and Q-switching. Also, the nonlinear refraction (Kerr effect) is crucial for functionalities including all-optical switching, signal regeneration, and fast optical communications.

One of the most intriguing and unique properties of GO is that its electrical and optical properties can be tuned dynamically by manipulating the content of oxygen-containing groups through either chemical or physical reduction methods. The tuning of the optical nonlinearities have been demonstrated during its entire laser-induced reduction process through continuous increase of the laser irradiance and four stages of different nonlinear activities have been discovered, which may serve as promising solid state materials for novel nonlinear functional devices.[43] It is also proved that metal nanoparticles can greatly enhance the optical nonlinearity[44] and fluorescence[45] of graphene oxide.

Graphene manufacture

Graphite oxide has attracted much interest as a possible route for the large-scale production and manipulation of graphene, a material with extraordinary electronic properties. Graphite oxide itself is an insulator,[46] almost a semiconductor, with differential conductivity[11] between 1 and 5×10−3 S/cm at a bias voltage of 10 V.[46] However, being hydrophilic, graphite oxide disperses readily in water, breaking up into macroscopic flakes, mostly one layer thick. Chemical reduction of these flakes would yield a suspension of graphene flakes. It was argued that the first experimental observation of graphene was reported by Hanns-Peter Boehm in 1962.[47] In this early work the existence of monolayer reduced graphene oxide flakes was demonstrated. The contribution of Boehm was recently acknowledged by Andre Geim, the Nobel Prize winner for graphene research.[48]

Partial reduction can be achieved by treating the suspended graphene oxide with hydrazine hydrate at 100 °C for 24 hours,[24] by exposing graphene oxide to hydrogen plasma for a few seconds,[46] or by exposure to a strong pulse of light, such as that of a Xenon flash.[49] Due to the oxidation protocol, manifold defects already present in graphene oxide hamper the effectiveness of the reduction. Thus, the graphene quality obtained after reduction is limited by the precursor quality (graphene oxide) and the efficiency of the reducing agent.[50] However, the conductivity of the graphene obtained by this route is below 10 S/cm,[49] and the charge mobility is between 0.1 and 10 cm2/Vs.[46][51][52] These values are much greater than the oxide's, but still a few orders of magnitude lower than those of pristine graphene.[46] Recently, the synthetic protocol for graphite oxide was optimized and almost intact graphene oxide with a preserved carbon framework was obtained. Reduction of this almost intact graphene oxide performs much better and the mobility values of charge carriers exceeds 1000 cm2/Vs for the best quality of flakes.[53] Inspection with the atomic force microscope shows that the oxygen bonds distort the carbon layer, creating a pronounced intrinsic roughness in the oxide layers which persists after reduction. These defects also show up in Raman spectra of graphene oxide.[46]

Large amounts of graphene sheets may also be produced through thermal methods. For example, in 2006 a method was discovered that simultaneously exfoliates and reduces graphite oxide by rapid heating (>2000 °C/min) to 1050 °C. At this temperature, carbon dioxide is released as the oxygen functionalities are removed and explosively separates the sheets as it comes out.[54]

Exposing a film of graphite oxide to the laser of a LightScribe DVD has also revealed to produce quality graphene at a low cost. [55]

Graphene oxide has also been reduced to graphene in situ, using a 3D printed pattern of engineered E. coli bacteria.[56]

Water purification

Graphite oxides were studied for desalination of water using reverse osmosis beginning in the 1960s.[57] In 2011 additional research was released.[58]

In 2013 Lockheed Martin announced their Perforene graphene filter. Lockheed claims the filter reduces energy costs of reverse osmosis desalination by 99%. Lockheed claimed that the filter was 500 times thinner than the best filter then on the market, one thousand times stronger and requires 1% of the pressure.[59] The product was not expected to be released until 2020.[60]

Another study showed that graphite oxide could be engineered to allow water to pass, but retain some larger ions.[59] Narrow capillaries allow rapid permeation by mono- or bilayer water. Multilayer laminates have a structure similar to nacre, which provides mechanical strength at water free conditions. Helium cannot pass through the membranes in humidity free conditions, but penetrates easily when exposed to humidity, whereas water vapor passes with no resistance. Dry laminates are vacuum-tight, but immersed in water, they act as molecular sieves, blocking some solutes.[61]

A third project produced graphene sheets with subnanoscale (0.40 ± 0.24 nm) pores. The graphene was bombarded with gallium ions, which disrupt carbon bonds. Etching the result with an oxidizing solution produces a hole at each spot struck by a gallium ion. The length of time spent in the oxidizing solution determined average pore size. Pore density reached 5 trillion pores per square centimeter, while retaining structural integrity. The pores permitted cation transport at short oxidation times, consistent with electrostatic repulsion from negatively charged functional groups at pore edges. At longer oxidation times, sheets were permeable to salt but not larger organic molecules.[62]

In 2015 a team created a graphene oxide tea that over the course of a day removed 95% of heavy metals in a water solution [63]

One project layered carbon atoms in a honeycomb structure, forming a hexagon-shaped crystal that measured about 0.1 millimeters in width and length, with subnanometer holes. Later work increased the membrane size to on the order of several millimeters.[64]

Graphene attached to a polycarbonate support structure was initially effective at removing salt. However, defects formed in the graphene. Filling larger defects with nylon and small defects with hafnium metal followed by a layer of oxide restored the filtration effect.[64]

In 2016 engineers developed graphene-based films that can filter dirty/salty water powered by the sun. Bacteria were used to produce a material consisting of two nanocellulose layers. The lower layer contains pristine cellulose, while the top layer contains cellulose and graphene oxide, which absorbs sunlight and produces heat. The system draws water from below into the material. The water diffuses into the higher layer, where it evaporates and leaves behind any contaminants. The evaporate condenses on top, where it can be captured. The film is produced by repeatedly adding a fluid coating that hardens. Bacteria produce nanocellulose fibers with interspersed graphene oxide flakes. The film is light and easily manufactured at scale.[65]

Coating

Optically transparent, multilayer films made from graphene oxide are impermeable under dry conditions. Exposed to water (or water vapor), they allow passage of molecules below a certain size. The films consist of millions of randomly stacked flakes, leaving nano-sized capillaries between them. Closing these nanocapillaries using chemical reduction with hydroiodic acid creates "reduced graphene oxide" (r-GO) films that are completely impermeable to gases, liquids or strong chemicals greater than 100 nanometers thick. Glassware or copper plates covered with such a graphene "paint" can be used as containers for corrosive acids. Graphene-coated plastic films could be used in medical packaging to improve shelf life.[66]

Related materials

Dispersed graphene oxide flakes can also be sifted out of the dispersion (as in paper manufacture) and pressed to make an exceedingly strong graphene oxide paper.[16]

Graphene oxide has been used in DNA analysis applications. The large planar surface of graphene oxide allows simultaneous quenching of multiple DNA probes labeled with different dyes, providing the detection of multiple DNA targets in the same solution. Further advances in graphene oxide based DNA sensors could result in very inexpensive rapid DNA analysis.[67] Recently a group of researchers, from university of L'Aquila (Italy), discovered new wetting properties of graphene oxide thermally reduced in ultra-high vacuum up to 900 °C. They found a correlation between the surface chemical composition, the surface free energy and its polar and dispersive components, giving a rationale to the wetting properties of graphene oxide and reduced graphene oxide.[68] [69]

Flexible rechargeable battery electrode

Graphene oxide has been demonstrated as a flexible free-standing battery anode material for room temperature lithium-ion[70] and sodium-ion batteries.[71][72] It is also being studied as a high surface area conducting agent in lithium-sulfur battery cathodes.[73] The functional groups on graphene oxide can serve as sites for chemical modification and immobilization of active species. This approach allows for the creation of hybrid architectures for electrode materials. Recent examples of this have been implemented in lithium ion batteries, which are known for being rechargeable at the cost of low capacity limits. Graphene oxide-based composites functionalized with metal oxides and sulfides have been shown in recent research to induce enhanced battery performance. This has similarly been adapted into applications in supercapacitors, since the electronic properties of graphene oxide allow it to bypass some of the more prevalent restrictions of typical transition metal oxide electrodes. Research in this field is developing, with additional exploration into methods involving nitrogen doping and pH adjustment to improve capacitance.[74] Additionally, research into reduced graphene oxide sheets, which display superior electronic properties akin to pure graphene, is currently being explored. Reduced graphene oxide applications greatly increases the conductivity and efficiency, while sacrificing some flexibility and structural integrity.[75][76][77]

Graphene oxide lens

This section needs additional citations for verification. (January 2017) |

The optical lens has been playing a critical role in almost all areas of science and technology since its invention about 3000 years ago. With the advances in micro- and nanofabrication techniques, continued miniaturization of the conventional optical lenses has always been requested for various applications such as communications, sensors, data storage and a wide range of other technology-driven and consumer-driven industries. Specifically, ever smaller sizes, as well as thinner thicknesses of micro lenses, are highly needed for subwavelength optics or nano-optics with extremely small structures, particularly for visible and near-IR applications. Also, as the distance scale for optical communications shrinks, the required feature sizes of micro lenses are rapidly pushed down.

Recently, the excellent properties of newly discovered graphene oxide provide novel solutions to overcome the challenges of current planar focusing devices. Specifically, giant refractive index modification (as large as 10^-1), which is one order of magnitude larger than the current materials, between graphene oxide (GO) and reduced graphene oxide (rGO) have been demonstrated by dynamically manipulating its oxygen content using direct laser writing (DLW) method. As a result, the overall lens thickness can be potentially reduced by more than ten times. Also, the linear optical absorption of GO is found to increase as the reduction of GO deepens, which results in transmission contrast between GO and rGO and therefore provides amplitude modulation mechanism. Moreover, both the refractive index and the optical absorption are found to be dispersionless over a broad wavelength range from visible to near infrared. Finally, GO film offers flexible patterning capability by using the maskless DLW method, which reduces the manufacturing complexity and requirement.

As a result, a novel ultrathin planar lens on a GO thin film has been realized recently using the DLW method.[78] The distinct advantage of the GO flat lens is that phase modulation and amplitude modulation can be achieved simultaneously, which are attributed to the giant refractive index modulation and the variable linear optical absorption of GO during its reduction process, respectively. Due to the enhanced wavefront shaping capability, the lens thickness is pushed down to subwavelength scale (~200 nm), which is thinner than all current dielectric lenses (~ µm scale). The focusing intensities and the focal length can be controlled effectively by varying the laser powers and the lens sizes, respectively. By using oil immersion high NA objective during DLW process, 300 nm fabrication feature size on GO film has been realized, and therefore the minimum lens size has been shrunk down to 4.6 µm in diameter, which is the smallest planar micro lens and can only be realized with metasurface by FIB. Thereafter, the focal length can be reduced to as small as 0.8 µm, which would potentially increase the numerical aperture (NA) and the focusing resolution.

The full-width at half-maximum (FWHM) of 320 nm at the minimum focal spot using 650 nm input beam has been demonstrated experimentally, which corresponding to the effective numerical aperture (NA) of 1.24 (n=1.5), the largest NA of current micro lenses. Furthermore, ultra-broadband focusing capability from 500 nm to as far as 2 µm have been realized with the same planar lens, which is still a major challenge of focusing in infrared range due to limited availability of suitable materials and fabrication technology. Most importantly, the synthesized high quality GO thin films can be flexibly integrated on various substrates and easily manufactured by using the one-step DLW method over a large area at a comparable low cost and power (~nJ/pulse), which eventually makes the GO flat lenses promising for various practical applications.

Energy conversion

Photocatalytic Water Splitting is an artificial photosynthesis process in which water is dissociated into hydrogen (H2) and oxygen (O2), using artificial or natural light. Methods such as photocatalytic water splitting are currently being investigated to produce hydrogen as a clean source of energy. The superior electron mobility and high surface area of graphene oxide sheets suggest it may be implemented as a catalyst that meets the requirements for this process. Specifically, graphene oxide's compositional functional groups of epoxide (-O-) and hydroxide (-OH) allow for more flexible control in the water splitting process. This flexibility can be used to tailor the band gap and band positions that are targeted in photocatalytic water splitting. Recent research experiments have demonstrated that photocatalytic activity of graphene oxide containing a band gap within the required limits has produced effective splitting results, particularly when used with 40-50% coverage at a 2:1 hydroxide:epoxide ratio. When used in composite materials with CdS (a typical catalyst used in photocatalytic water splitting), graphene oxide nanocomposites have been shown to exhibit increased hydrogen production and quantum efficiency.

Hydrogen storage

Graphene oxide is also being explored for its applications in hydrogen storage. Hydrogen molecules can be stored among the oxygen-based functional groups found throughout the sheet. This hydrogen storage capability can be further manipulated by modulating the interlayer distance between sheets, as well as making changes to the pore sizes. Research in transition metal decoration on carbon sorbents to enhance hydrogen binding energy has led to experiments with titanium and magnesium anchored to hydroxyl groups, allowing for the binding of multiple hydrogen molecules.

Toxicity

Several typical mechanisms underlying graphene (oxide) nanomaterials toxicity have been revealed, for instance, physical destruction, oxidative stress, DNA damage, inflammatory response, apoptosis, autophagy, and necrosis. In these mechanisms, (toll-like receptors-) TLR-, transforming growth factor β- (TGF-β-) and tumor necrosis factor-alpha (TNF-α) dependent-pathways are involved in the signalling pathway network, and oxidative stress plays a crucial role in these pathways. Many experiments have shown that graphene (oxide) nanomaterials have toxic side effects in many biological applications, but more in-depth study of toxicity mechanisms is needed.[79] According to the USA FDA, graphene, graphene oxide, and reduced graphene oxide elicit toxic effects both in vitro and in vivo.[80] Graphene-family nanomaterials (GFN) are not approved by the USA FDA for human consumption.

-

Ei kommentteja:

Lähetä kommentti

You are welcome to show your opinion here!